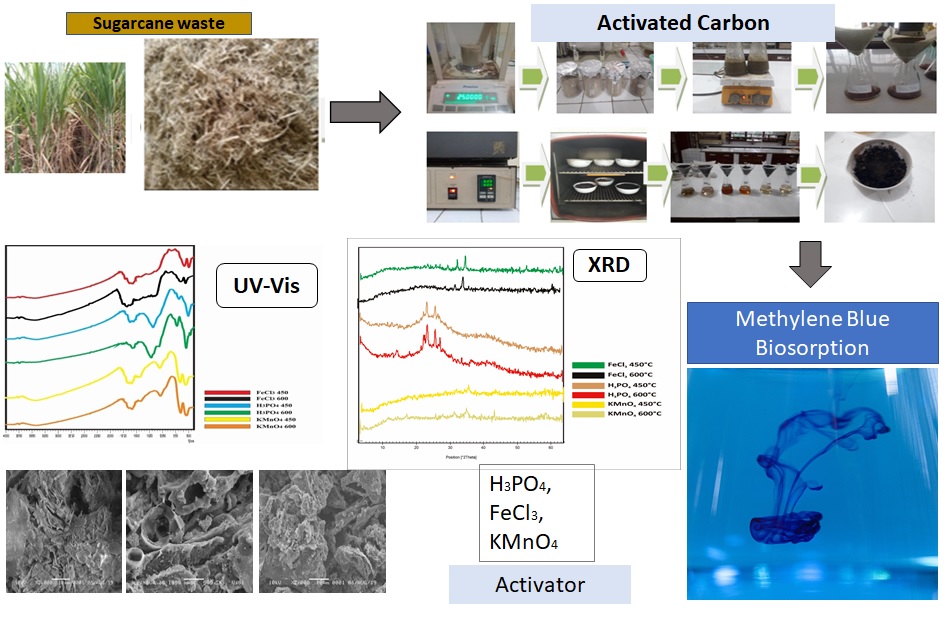

Biosorption of Methylene Blue by Activated Carbon from Sugarcane Waste (ACSW)

Abstract

This study was aimed to produce and characterized activated carbon from sugarcane bagassebyphysical and chemicalactivation. Physical activation was performed by carbonation process in temperatures 4500C and 6500C. While chemical activationusedH3PO4 10%, FeCl3 10% and KMnO4 10% as activator. The results showed that total yield (%) 49.8396 - 80.635; pH 4.0-7.9; ash content (g) 0.3338-0.8820; adsorption capacity of iod (%) 93.92-99.20. Morphological structure, functional group and Crystal structure was studied by using SEM analysis, FT-IR and XRD Difragtogram respectively.Adsorption capacity(%) of methylene blue 1.5 ppm and 2.5 ppm using UV-VIS Spectrophotometer produces; for H3PO4activatorat 450℃ = 99.24 and ND;at 600℃ = ND and 99.24. FeCl3 activator at 450℃ = 93.8 and 28.68; At 600℃ = ND and 99.24. KMnO4 activator at 450℃ = 61.24 and 65.12; At 600℃ = 39.4 and 53.79.

References

[1] Hao, P., Zhao, Z., Tian, J., Li, H., Sang, Y., Yu, G., Cai, H., Liu, H., Wong, C.P. and Umar, A, Nanoscale, 2014, 6 (20), 12120-12129.

[2] Kharat, D.S, Braz. J. Chem. Eng, 2015, 32, 1-12.

[3] Abdel-Raouf, M.S. and Abdul-Raheim, A.R.M, J Pollut Eff Cont, 2017, 5, 180.

[4] Zhang, Z., Qu, Y., Guo, Y., Wang, Z. and Wang, X, Colloids Surf. A Physicochem. Eng. Asp, 2014, 447, 183-187.

[5] Ioannidou, O. and Zabaniotou, A., Renewable and sustainable energy reviews, 2007, 11 (9), 1966-2005.

[6] Sarker, T.C., Azam, S.M.G.G., Abd El-Gawad, A.M., Gaglione, S.A. and Bonanomi, G, Clean Technol Environ Policy, 2017, 19 (10), 2343-2362.

[7] Zhang, Z., Qu, Y., Guo, Y., Wang, Z. and Wang, X., Wang, Z. and Wang, X, Colloids Surf. A Physicochem. Eng. Asp, 2014, 447, 183-187.

[8] Doczekalska, B.E.A.T.A., Bartkowiak, M.O.N.I.K.A., Orszulak, G.R.A.Ż.Y.N.A. and Katolik, Z.B.I.G.N.I.E.W, Forestry and Wood Technology, 2015, 92.

[9] González-García, P, Renewable and Sustainable Energy Reviews, 2018, 82, 1393-1414.

[10] Kyzas, G. Z. and Deliyanni, E. A, Eng. Res. Des, 2015, 97, 135-144.

[11] Aajish, L.G. and Thirumal, J, IOSR-JESTFT, 2014, 8 (5), 28-33.

[12] Devnarain, P.B., Arnold, D.R. and Davis, S.B., Proc S Afr. Sug. Technol. Ass, 2002, 76, 477-489.

[13] Guan, B.T., Latif, P.A. and Yap, T.Y, Int. J. Eng. Res. Sci. Technol, 2013, 2, 1-14.

[14] Ahiduzzaman, M. and Islam, A.S, SpringerPlus, 2016, 5 (1), 1-14.

[15] Mohamed, N.B., Ngadi, N., Lani, N.S. and Rahman, R.A, Chem. Eng. Trans, 2017, 56, 103-108.

[16] Veksha, A., Uddin, A., Sasaoka, E. and Kato, Y., J. Chem. Eng. Japan J CHEM ENG JPN, 2012, 1203010337-1203010337.

[17] Khoshnabadi, R.J., Lotfi, H. and Vadi, M., Res. j. pharm. biol. chem. sci., 2015, 6 (3),1469-1475.

[18] Seixas, F., Goncalves, E., Olsen, M., Gimenes, M.L. and Fernandes-Machado, N., Chem. Eng. Trans., 2017, 57, 139-144.

[19] Zubrik, A., Matik, M., Hredzák, S., Lovás, M., Danková, Z., Kováčová, M. and Briančin, J., J. Clean. Prod, 2017, 143, 643-653.

[20] Grycova, B., Pryszcz, A., Matejova, L and Lestinsky, P., Chem. Eng. Trans, 2018, 70, 1897-1902.

[21] Castro, J. B., Bonelli, P. R., Cerrella, E. G and Cukierman, A L, Ind. Eng. Chem. Res, 2000, 39 (11), 4166-4172.

[22] Saiful Azhar, S., Abdul Ghaniey Liew, A., Suhardy, D., Farizul Hafiz, K and Hatim, M. I, Am.J. Appl. Sci, 2005, 2 (11).

[23] Mathivanan, M. and Saranathan, E. S., J. chem. pharm., 2015, 7 (1), 817-822.

[24] Chaiwon, T., Jannoey, P and Channei, D. A. D, Key Engineering Materials, 2017, 751, 671-676.

[25] Mazlan, M. A. F., Uemura, Y., Yusup, S., Elhassan, F., Uddin, A., Hiwada, A and Demiya, M., Procedia eng, 2016, 148, 530-537.

[26] Foo, K. Y., Lee, L. K and Hameed, B. H., Bioresour. technol, 2013, 134, 166-172.

[27] Adowei, P., Abia, A. A and Spiff, A. I, Res J Chem Sci, 2015, 5 (1), 18-26.

[28] Rodríguez, G. R, Nitrate and phosphate removal from aqueous solutions by biochar and agro-forestry residues, Doctoral dissertation, Master Thesis, Royal Institute of Technology, 2012.

[29] Kunusa, W. R., Isa, I., Laliyo, L. A and Iyabu, H., J. Phys. Conf. Ser, 2018, 1, 012199.

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.