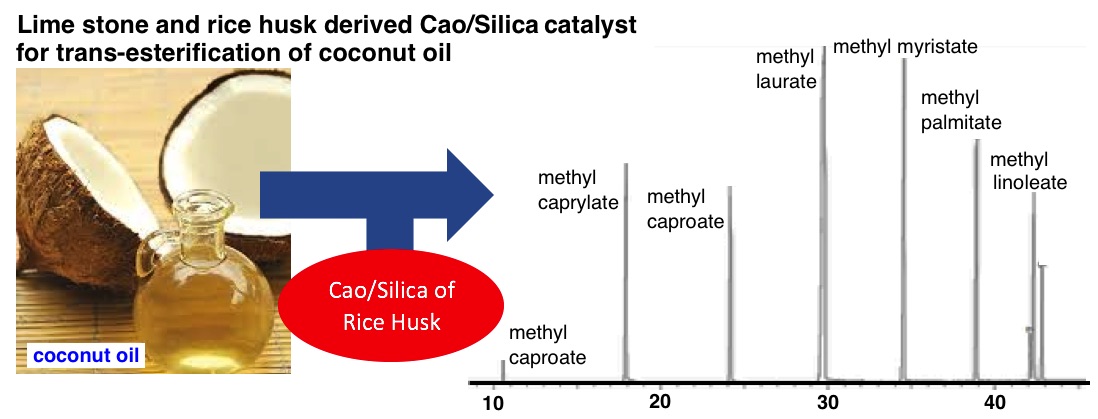

Catalytic Performance of CaO/SiO2 Prepared from Local Limestone Industry and Rice Husk Silica

Abstract

This research was conducted to study the performance of CaO/SiO2 prepared from local limestone and rice husk silica as catalyst for transesterification of coconut oil. A series of catalysts with CaO loads of 5, 10, 15, 20, and 25% relative to silica was prepared using sol-gel method, followed by calcination at 700 °C for six hours. The catalysts were then used to evaluate the effect of CaO loads on percent of conversion of coconut oil. Several kinetic factors associated with transesterification was also investigated. The products of transesterification were analyzed using GC-MS technique, revealing that they are composed methyl esters of fatty acid composing coconut oil. Quite significant effect of CaO loads observed, in which the higher the load, the higher the percent of conversion. However, it should be noted that the use of 25% CaO led to formation of soap due to leaching of some CaO from the catalyst. Taking this leaching into account, it was then concluded that percent of conversion of 98.3%, is the best result, which was obtained with the use of catalyst with CaO load of 20%, reaction time of 60 minutes, methanol to oil ratio of 8:1, and the catalyst amount of 5% relative to mass of the oil.

References

[1] Goff, M. J., Bauer, N. B., Lopes, S., Sutterlin, R., & Suppes, G. J. J. Am. Oil. Chem.’ Soc., 2004, 81 (4), 415 – 420.

[2] Jain, S., Sharma, M. P., & Rajvanshi, S. Fuel Process. Technol., 2011, 92(1), 32 – 38.

[3] Aladetuyi, A., Olatunji, G. A., Ogunniyi, D. S., Odetoye, T. E., & Oguntoye, S. O. Biofuel Res. J., 2014, 1(4), 134 – 138.

[4] Gardy, J., Rehan, M., Hassanpour, A., Lai, X., & Nizami, A.S., J. Environ. Manage. 2019, 249, 109316.

[5] Pandiangan, K. D. & Simanjuntak, W. Indones. J. Chem., 2013, 13 (1), 47 – 52.

[6] Ali, A., Khullar, P., & Kumar, D. Energ. Source. Part A, 2014, 36(18), 1999 – 2008.

[7] Gurunathan, B. & Ravi, A., Bioresour. Technol., 2015, 188, 124 – 127.

[8] Pandiangan, K. D., Jamarun, N., Arief, S., & Simanjuntak, W., Orient. J. Chem., 2016, 32 (1), 385 – 390.

[9] Mohadesi, M., Hojabri, Z., & Moradi, G. Biofuel Res. J., 2014, 1(1), 30 – 33.

[10] Kutálek, P., Capek, L., Smoláková, L., Kubicka, D. Fuel Process. Technol., 2014, 122, 176 – 181.

[11] Mohadi, R., Sueb, A., Anggraini, K., & Lesbani, A. J. Pure App. Chem. Res., 2018, 7 (2), 130 – 139.

[12] Ketcong, A., Meechan, W., Naree, T., Seneevong, I., Winitsorn, A., Butnark, S., Ngamcharussrivichai, C. J. Ind. Eng. Chem., 2014, 20(4), 1665 – 1671.

[13] Pandiangan, K. D., Jamarun, N., Arief, S., Simanjuntak, W., Rilyanti, M. Orient. J. Chem., 2016, 32 (6), 3021 – 3026.

[14] Pandiangan, K. D., Simanjuntak, W., Rilyanti, M., Jamarun, N., Arief, S., Orient. J. Chem., 2017, 33 (6), 2891 – 2898.

[15] Zabeti, M., Daud, W. M. A. W., & Aroua, M. K. Fuel Process. Technol., 2010, 91(2), 243 – 248.

[16] Teo, S. H., Taufiq-Yap, Y. H., Ng, F.L. Energ. Convers. Manage., 2014, 88, 1193 –1199.

[17] Moradi, G., Mohadesi, M., Rezaei, R., Moradi, R. Can. J. Chem. Eng., 2015, 93(9), 1531 – 1538.

[18] Wu, H., Zhang, J., Wei, Q., Zheng, J., Zhang, J. Fuel Process. Technol., 2013, 109, 13 – 18.

[19] Hassani, M., Najafpour, G. D., Mohammadi, M. J. Mater. Environ. Sci., 2016, 7(4), 1193 – 1203.

[20] Zabeti, M., Daud, W. M. A. W., & Aroua, M. K. Appl. Catal., A, 2009, 366(1), 154 – 159.

[21] Simanjuntak, W., Sembiring, S., Pandiangan, K. D., Syani, F., & Situmeang, T.M., Orient. J. Chem., 2016, 32 (4), 2079 – 2085.

[22] Elkady, M. F., Zaatout, A., & Balbaa, O. J. Chem., 2015, 2015, 630168.

[23] Lee, H.V., Juan, J.C., & Taufiq-Yap, Y.H., Renew. Energ., 2015, 74, 124-132.

[24] Moradi, G., Mohadesi, M. & Hojabri, Z. Reac. Kinet. Mech. Cat., 2014, 113(1), 169 – 186.

[25] Khandekar, U., Bhaise, P., Verulkar, P., Ghongade, R. Am. J. PharmTech Res., 2016, 6 (2), 242 – 249.

[26] Lani, N. S., Ngadi, N., Taib, M. R. Chem. Eng. Trans. 2017, 56, 601 – 606.

[27] Widayat, W., Darmawan, T., Hadiyanto, H. & Rosyid, A.R., J. Phys. Conf. Ser., 2017, 877(1), 012018.

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.