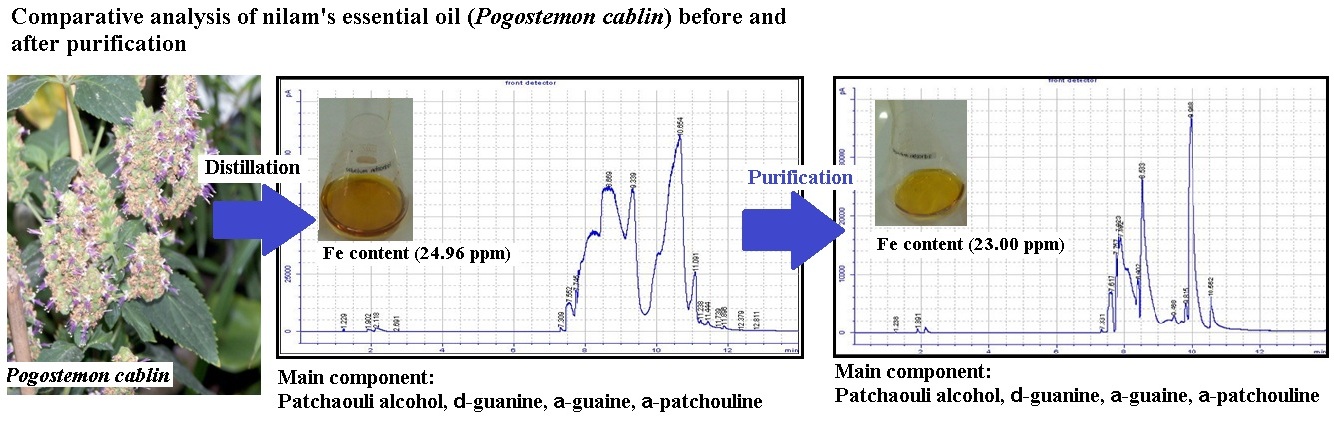

Comparative Analysis of Chemical Components of Purified Essential Oil from Nilam Plants using Gas Chromatography

Abstract

References

[1] Herlina, B., 2006. Pengaruh Volume Air Dan Berat Bahan Pada Penyulingan Minyak Atsiri.(online) http://jurtek.akprind.ac.id/sites/default/files/hal-83-88-sumarni-gabung-ok.pdf (Accessed date : 15 October 2015)

[2] Harahap, 2009, Karakterisasi dan simplisia dan isolasi serta analisis komponen minyak atsiri pada daun nilam (http://repository.usu.ac.id/bitstream/123456789/14328/1/09E01539.pdf) (Accessed date : 20 October 2012)

[3] Ma’mun, Jurnal Littri Puslitbang Perkebunan, 2008, 14(1), 12.

[4] Priambodo, N.G., Thesis, Pemurnian Minyak Nilam Menggunakan Bentonit Teraktivasi Asam Klorida, Bachelor UIN Sunan Kalijaga, 2014.

[5] Setianto, M.S and Riwayati, I., Pemanfaatan Limbah Penyulingan Daun Nilam Sebagai Bahan Bakar Alternatif Melalui Pembuatan Briket, Semarang, Wahid Hasyim University.

[6] Handayani, P. A. and Widiarti, N., Thesis, Penerapan Teknologi Pemurnian Minyak Cengkeh Sebagai Upaya Peningkatan Kesejahteraan Pengrajin di Kecamatan Ungaran Barat. Semarang : Universitas Negeri Semarang, 2010.

[7] Tri Marwati and Hernani, Peningkatan Mutu Minyak Atsiri melalui Proses Pemurnian, Balai Besar Litbang Pascapanen Pertanian, 2006, Konferensi Nasional Minyak Atsiri.

[8] Sariadi, Jurnal Teknologi, 2012, 12(2), 100-104.

[9] Saraswati, A and Nugraha, I., Sintesis Komposit Montmorillonit- TiO2 dan Aplikasinya untuk Pengolahan Limbah Cair Pabrik Gula, 2014, Prosiding Seminar Nasional Kima dan Pendidikan Kimia VI.

[10] Septiana, A., Jurnal Teknologi Kimia dan Industri, 2013, 2(2), 257-261.

[11] Indeswari, N. S., IJASEIT, 2015, 5(1), 13-15.

[12] Kumar, P., and Jasra, V., Ind. Eng. Chem. Res., 1995, 34, 1440-1448.

[13] Jeenpadiphat, S., and Tungasmita, D. N., Powder Technol., 2013, 237, 634-640.

[14] Nasrat, L., Abdelwahab, M., Ismail, G., Eng. Sci. Res., 2011, 3, 588-593.

[15] Greek, S. J., Adsorption, Surface Area, and Porosity, 1982, Academic Press, London

[16] Singh, M., Sharma, S., Ramesh, S., Ind. Crops Prod., 2002, 16, 101-107.

[17] Srikrishna, A., Satyanarayana, G., Asymmetry, 2005, 16, 3992-3997.

[18] C. Wildwood, 1994, O livro dos perfumes, Sao Paulo, Brazil.

[19] A. Donelian, L. H. C. Carlson, T. J. Lopes, R. A. F. Machado, J Supercrit Fluids, 2009, 48, 15-20.

[20] Blank, A. F., Sant’ana, T. C., Santos, P. S., Arrigoni-Blank, M. F., Prata, A. P. d. N., Jesus H. C. R., Alves, P. B., Ind. Crops Prod., 2011, 34, 831-837.

Refbacks

- There are currently no refbacks.