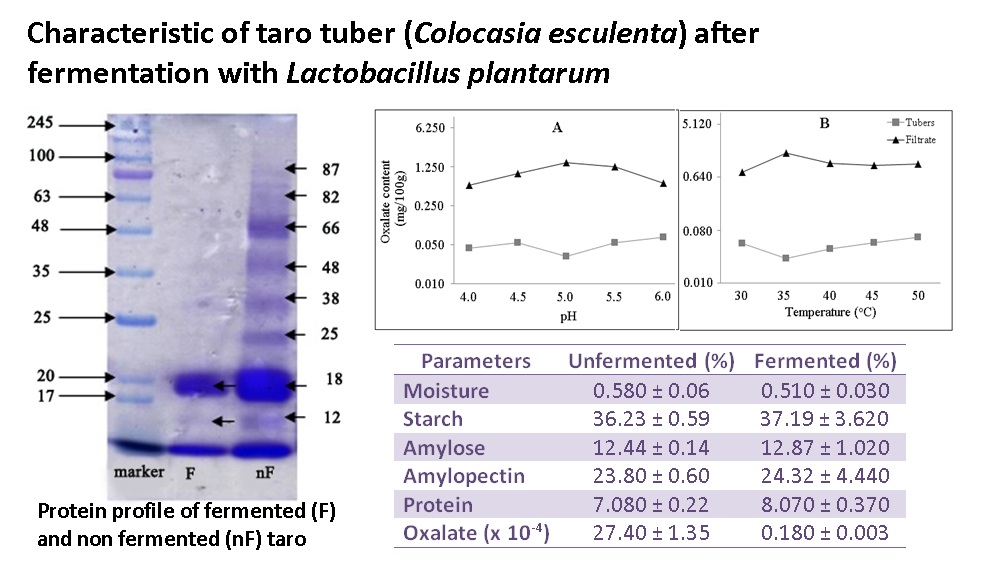

Antinutritional Content, Flour Characteristics, and Protein Profiles of Taro Tubers (Colocasia esculenta) by Fermentation with Lactobacillus plantarum

Abstract

The purpose of this research was studying the optimum condition, the change of oxalate content, the characteristic of flour, and protein profile of taro tuber that fermented with Lactobacillus plantarum. The optimum condition of fermentation was determined based on the lowest oxalate content in flour. The optimum conditions of fermentation studied were variation of pH (4-6), temperature (30⁰–50 ⁰C) and incubation time (6–48 hours). The result showed that the optimum condition of fermentation was achieved at pH 5, 35 °C in 48 h incubation time. The fermented taro flour characteristics were the increasing level of starch (4.76%), amylose (0.43%). amylopectin (4.36%) and protein (0.99%). The fermented taro protein profiles showed that the allergenic proteins were not present, suggesting those proteins were missing due to fermentation process.

References

[1] M. Arici, R. M. Yildirim, G. Ozulku, B. Yasar, and Omer Said Toker, LWT - Food Sci. Technol., 2016, 74, 434–440.

[2] P. Kaushal, V. Kumar, and H. K. Sharma, LWT - Food Sci. Technol., 2012, 48, 59–68.

[3] A. Cahyo, R. Dewi, A. Putri, C. Sri, and D. Susetyo, Procedia Chem., 2014, 9, 102–112.

[4] G. Reddy, B. J. Naveena, M. Venkateshwar, and E. V. Kumar, Biotechnoligy Advances, 2008, 26, 22–34.

[5] Tefera T., A. K, and B. A., Int. Food Res. J., 2014, 21, 1751–1756.

[7] S. C. Kobawila, D. Louembe, S. Keleke, J. Hounhouigan, and C. Gamba, African Journal of Technology, 2005, 4, 689–696.

[8] S. M. Adeyemo and A. A. Onilude, Niger. Food J., 2013, 31, 84–90.

[9] S. Williams, Official Methods Of Analysis. 14th ed. 1984, AOAC, INC, Virginia.

[10] Y. Pranoto, S. Anggrahini, and Z. Efendi, Food Biosci., 2013, 2, 46–52.

[11] R. Setiawan, Penentuan Kondisi Optimum Fermentasi Menggunakan Lactobacillus bulgaricus dalam Pembuatan Tepung Singkong Terfermentasi, Skripsi, Departemen Kimia Fakultas MIPA UB, Malang, 2011.

[12] R. Haryo, B. Setiarto, and N. Widhyastuti, JIPI, 2016, 21, 7–12.

[13] Buckle, K.A., R.A. Edward, G.H. Fleet, Wootton M, H. Purnomo, Adiono, Ilmu Pangan, 1987, UI-Press, Jakarta.

[14] E. T. Otunola, O. J. Oyelade, Food Science and Quality Management, 2015, 39, 98-110.

[15] Salminen, S. and A. V. Wright, Lactic Acid Bacteria, 1993, Marcel Dekker, Inc. New York.

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.