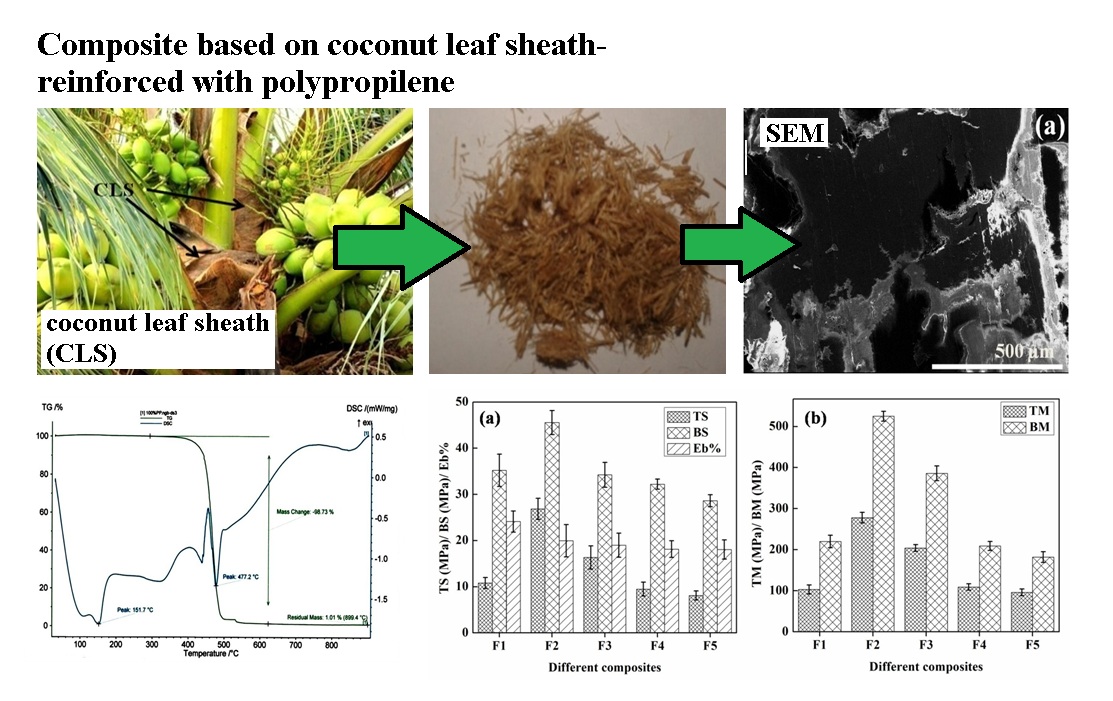

Study of Naturally Woven Coconut Leaf Sheath-Reinforced Polypropylene Matrix Based Composites

Abstract

Renewable materials have gained significant attraction as reinforcement in polymer matrix composites. Naturally woven coconut leaf sheath (CLS) fiber-reinforced polypropylene (PP) composites were prepared by compression molding. Different composites were fabricated varying the weight percentage of CLS fiber (5, 10, 15, 20 and 25 wt%) . Hydrophilic nature of the CLS fiber was evaluated using water uptake test. Structural feature of the composites was confirmed by infrared spectroscopy. Mechanical performance was investigated using tensile and bending tests. Fiber reinforcement significantly increased the mechanical properties of the composites. Moreover, thermal properties and degradation nature of the composites were investigated.

References

[1] Mohanty A. K, Misra M. andHinrichsen G., Macromol Mater Eng, 2000, 276/ 277, 1–24. website

[2] Mittal V., Saini R., and Sinha S., Composites Part B, 2016, 99, 425-435. crossref

[3] Riccieri J. E., De Carvalho L. H. and Vazquez A., Polym Composite, 1999, 20(1), 29–37. website

[4] Woodhams R., Thomas T. G., and Rodgers D. K., Polym Eng Sci, 1984, 24(15), 1166-1171. website

[5] Klason C. and Kubat J., Cellulose in polymer composites, composite system from natural and synthetic polymers, Salmen L. et al. edition, 1986, Elsevier Science, Amsterdam.

[6] Kuruvilla J., Siby V., Kalaprasad G., Thomas S, Prasannakumari L and Pavithran C, Euro Poly J, 1996, 32, 1243-1250. crossref

[7] Oksman K., Wallström L., Berglund L. A. and Filho R. D. T., J App Polym Sci, 2001, 84, 2358-2365. website

[8] De Albuquerque A. C., Kuruvilla J., De Carvalho L. H. and d’Almeida J. R. M., Comp Sci Tech, 2000, 60, 833-844. crossref

[9] Abdullah-Al-Kafi and Abedin M. Z., J Reinf Plast Comp, 2006, 25, 575-588. website

[10] Wisittanawata U., Thanawanb S., and Amornsakchai T., Polym Test, 2014, 35, 20–27. crossref

[11] George J. Sreekala M. S. and Sabu T., J Reinf Plast Comp, 1998, 17, 651-672. website

[12] Srinivasana V.S., Boopathya S.R., Sangeethaa D., and Ramnath B.V., Mater Design, 2014, 60, 620–627. crossref

[13] Benítez A. N., Monzón M. D., Angulo I., Ortega Z., Hernández P. M. and Marrero M. D., Measurement, 2013, 46, 1065–1073. crossref

[14] Pothan L. A. Sabu T. and Neelakantan N. R., J Reinf Plast Comp, 1997, 16, 744-765. website

[15] Kabir H. Gafur M. A. Ahmed F. Begum F. and Qadir M. R., Universal J Mater Sci, 2014, 2(6), 119-124. website

[16] K. M. M. Rao, K. M. Rao, Compos Struct, 2007, 77, 288-295. crossref

[17] Mohanty J. R., Das S. N., Das H. C., and Swain S. K., Polym Composite, 2013, 34(6), 959-966. website

[18] Rozman H. D., Tay G. S., Kumar R. N., Abubakar A., Ismail H., and Ishak Z. A. M, Polym Plast Tech Eng, 1999, 38, 997-1011. website

[19] Abdul K., Hanida S., Kang C. W., and Fuad N. A., Reinf Plast Comp, 2009, 26, 203-218. website

[20] Dey K., Sharmin N., Khan R. A., Nahar S., Parsons A. J., and Rudd C. D., J Thermoplast Compos, 2011, 24, 695-711. website

[21] Garcia M. Vliet G. V., Jain S., Zyl W. E..V., and Boukamp B., Rev Adv Mater Sci, 2004, 6, 169-175. website

[22] Karmaker A. C. and Hinrichsen G., Polym Plast Technol Eng, 1999, 30, 609-621. website

[23] Khan M. A., Hinrichsen G., and Drzal L. T., J Mat Sci Lett, 2001, 20, 1211-1713. website

[24] Bledzki A. K. and Gassan J., J Prog Polym Sci, 1999, 24, 221-274. crossref

[25] Wambua P., Ivan J., Verport I., J Comp Sci Tech, 2003, 63, 1259–1264. crossref

[26] Czvikovszky T., Nuclear Instr Methods Phys Res B, 1995, 105, 233–237. crossref

[27] Rahman M. M. and Khan M. A., Compos Sci Tech, 2007, 67, 2369-2376. crossref

[28] Poddar P., Asad M., Islam M. A., Sultana S., Nur S. P., and Chowdhury A. M. S., Adv Mater Sci, 2016, 1(2), 1-4.

[29] Mishra S., Mohanty A. K., Drzal L. T., Misra M., Parija S., Nayak S. K., and Tripathy S. S., Compos Sci Technol, 2003, 63(10), 1377. crossref

[30] Cantero G., Arbelaiz A., Llano-Ponte R., and Mondragon I., Compos Sci Technol, 2003, 3, 1247-1254. crossref

[31] Thwe. M. M. and Liao K., Compos Part A- Applied Sci Manuf, 2002, 33, 43–52. crossref

[32] Soykeabkaew N., Supaphol P., and Rujiravanit R., Carbohy Polym, 2004, 58, 53-63. crossref

[33] Björdal C. G., J Cult Herit. 2012, 13(3), 118–S122. crossref

Refbacks

- There are currently no refbacks.

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.